In today's rapidly changing/evolving world, there is a growing need for efficient/sustainable energy solutions. Pellet technology emerges as a effective answer to this demand. Pellet stoves and boilers extract the power of compressed wood pellets, offering a clean/green heating option that is both economical and environmentally friendly/eco-conscious.

Wood pellets are primarily made from sawmill waste and other forestry residues, making them a replenishable resource. When burned, pellets produce significantly minimal emissions compared to traditional fossil fuels, contributing/helping air pollution and promoting/supporting a healthier environment.

Furthermore/Additionally, pellet technology boasts high/excellent energy efficiency. Modern pellet stoves and boilers are designed to optimize/maximize heat output while minimizing waste, resulting in significant energy savings/cost reductions. This performance makes pellets an ideal/suitable choice for both homeowners and businesses seeking to reduce their reliance on fossil fuels.

The Definitive Guide to Pelletization Processes

Pelletization is a vital manufacturing process used to convert powdered or granular materials into small, uniform cylindrical pellets. This process offers numerous pros, including enhanced flowability, reduced dust emissions, and improved density. Pelletization processes are widely employed in diverse industries such as agriculture, pharmaceuticals, and construction.

There are various methods of pelletization, each with its unique characteristics. Some common methods include: dry binding, wet processing, and fluidized bed formation.

- Moreover, the choice of pelletization process depends on factors such as material properties, desired pellet size, and production scale.

- Grasping these variables is essential for optimizing the pelletization process and achieving the desired results.

This comprehensive guide will delve into the intricacies of pelletization processes, exploring various aspects, including: process concepts, equipment criteria, and quality control measures.

Biomass Pellets: Renewable Energy for a Greener Future

Biomass pellets are an increasingly popular alternative to traditional fossil fuels. These compact, cylindrical energy sources are made from compressed organic matter, such as wood waste, agricultural residues, and even algae. Utilizing readily available and renewable resources, biomass pellets offer a sustainable solution for generating heat and power. The combustion process releases energy while emitting significantly fewer greenhouse gases compared to fossil fuels. Furthermore, the production of biomass pellets can contribute to economic growth by creating jobs in forestry and agriculture sectors. As we strive towards a more environmentally friendly future, biomass pellets stand as a viable and promising option for reducing our reliance on finite resources and mitigating climate change.

Analyzing Pellet Properties for Optimal Performance

Pellet diameter play a crucial role in determining the efficiency and performance of combustion systems. Fine-tuning these properties including pellet density, moisture content, and shape is essential for achieving optimal burn rate.

A thorough analysis of these factors allows engineers to create pellets that meet the specific requirements of various applications.

For instance, in biomass boilers, high-density pellets with low moisture content are preferred for maximum heat generation. Conversely, in residential wood stoves, smaller particles may be more suitable due to the constraints of the combustion chamber.

By understanding the relationship between pellet properties and performance, manufacturers can fabricate pellets that maximize energy output while minimizing emissions. This results in a more sustainable and environmentally friendly approach to fuel combustion.

The Science Behind Pellet Production: From Raw Materials to Finished Product

The production of wood pellets is a fascinating procedure that involves several key phases. It all starts with raw ingredients, typically sourced from forest residues and sawmill scraps. These materials are carefully chosen for their suitability in producing high-quality pellets.

The first phase is the moisture reduction of the raw materials. This procedure is crucial to guarantee that the pellets have optimal moisture content for efficient combustion. Once dried, the materials are then processed into small pieces, known as feedstock.

Next, the raw material is moved to a pellet mill, where it undergoes a high-pressure compaction method. This procedure forces the ingredients through a die, creating cylindrical pellets of uniform size and shape. read more

After compaction, the pellets are then tempered to ensure their strength. Finally, the finished pellets are sorted to remove any undesirable fragments.

Applications of Pellets in Industries Worldwide

Pellets have emerged as a versatile and valuable resource across numerous industries worldwide. Their compact nature makes them perfect for shipping and storage, while their uniform size allows for efficient processing in various applications.

In the horticultural sector, pellets are used as a protein-rich feed source for livestock and poultry. In the construction industry, wood pellets serve as a eco-friendly alternative to fossil fuels for heating and power generation. Additionally, pellet technology finds applications in production processes, where pellets are used as raw materials or fuel sources.

The increasing demand for pellets is driven by their financial benefits, environmental friendliness, and versatility.

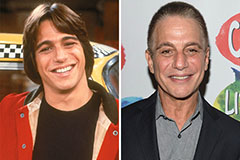

Tony Danza Then & Now!

Tony Danza Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!